Technologies

Learn everything about our production!

Experience perfection and precision: cutting-edge textile finishing in our 20,000 square metre production plant in Zittau

Pretreatment

Our machinery is capable of processing a wide range of fabric types up to a width of 200 cm. These include natural fibres as well as synthetic materials and their blends. Our expertise includes the processing of nonwovens, felts, cross-elastic fabrics, foams, membranes and films. This diversity enables us to respond flexibly to the different requirements and specifications of our customers.

Step by step to perfection

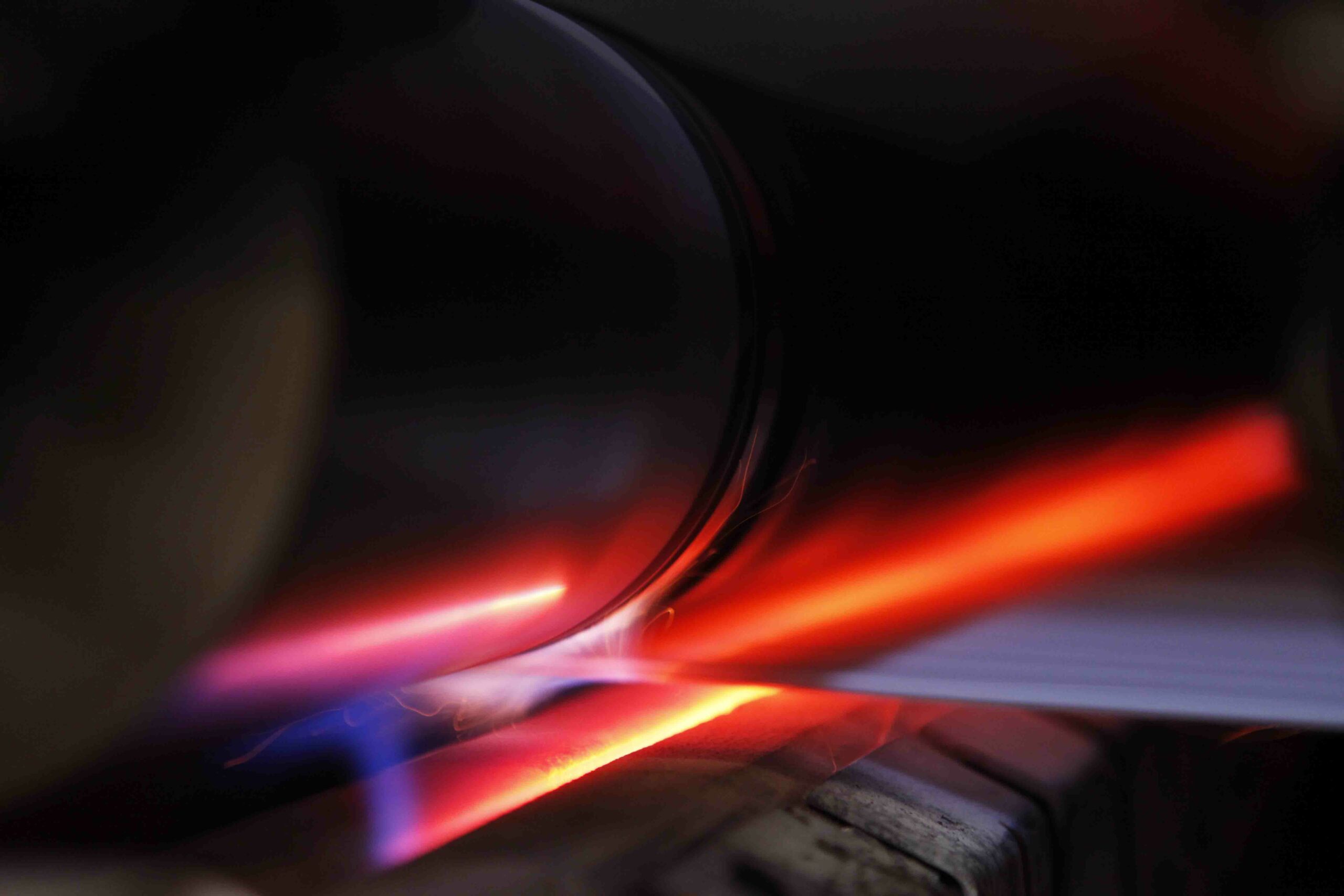

To optimise the production processes, the materials undergo a multi-stage pre-treatment consisting of singeing, desizing, bleaching and mercerising. The processed textiles include native fibres and synthetics in blends (nonwovens, felts, cross-elastic fabrics, foams, membranes and films).

Our finishing processes

Our comprehensive range of professional services is aimed at a wide range of customers.

Coating

Application of a visible plastic layer on a textile substrate to modify properties.

Lamination

Joining of two or more layers by heat or pressure to modify physical properties.

Solvent coating

Coating process for textiles for use in trenchless sewer rehabilitation.

Colouring and printing

Application of colours, patterns or dyeing of textiles using printing and dyeing techniques such as digital printing, rotary printing, dye baths, etc.

Mechanical finishing

- Calendering: Calibration of fabrics to achieve technical and optical requirements such as air permeability or gloss.

- Roughening: Optimisation of the grip and thermal insulation of the fabric.

- Sanforising: This prevents subsequent shrinkage of the product and thus an undesirable dimensional change.

Colouring and printing

- Description: Application of colours, patterns or dyeing of textiles using printing and dyeing techniques such as digital printing, rotary printing, dye baths, etc.

- Process: We offer 6 different dyeing processes in broad and rope form (reactive, substantive, pigment, sulphur, acid and metal complex). 16 dyeing systems with KKV, jigger, AT jigger, thermosol and rope dyeing support the process chain.

- Applications and effects: Colouring, changing the optical properties, improving the colour fastness and appearance of the textile.